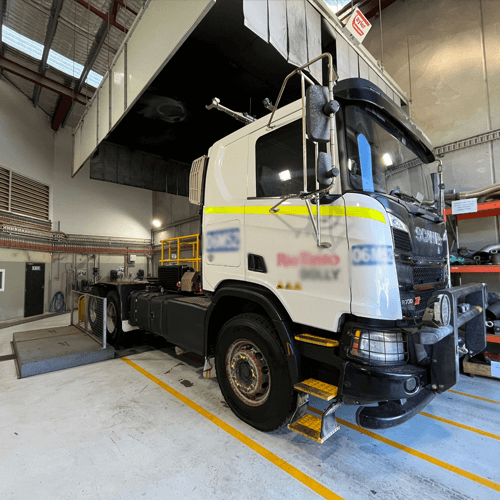

Mining Truck Maintenance

Services in Perth

Efficient, cost-effective mining trucks maintenance services to maintain performance,

safety, and

lifespan of your mining vehicles in demanding operational environments.

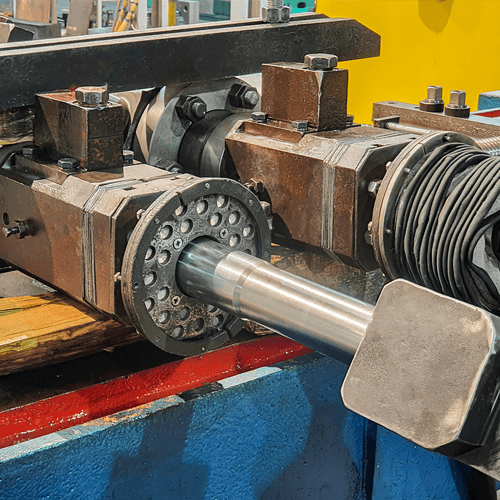

Onsite Vehicle Repairs and Maintenance

Onsite vehicle repairs and maintenance involve addressing vehicle issues directly at your mining site, eliminating the need to transport equipment to offsite facilities. This approach saves time and reduces operational disruptions, ensuring that your fleet remains productive. Our skilled technicians arrive equipped to handle diagnostics, repairs, and routine maintenance, providing swift solutions that keep your operations running smoothly.

By choosing West Fleet Care’s onsite services, you benefit from minimized downtime and enhanced efficiency. Our prompt response to maintenance needs helps prevent minor issues from escalating into major problems, thereby extending the lifespan of your equipment and reducing long-term costs. We are committed to delivering high-quality, convenient maintenance solutions tailored to the demanding needs of the mining industry.

Why Choose West Fleet Care?

Advanced Vehicle Diagnostic Technology

We use the latest diagnostic tools to accurately and efficiently identify and address complex mechanical and electrical vehicle issues.

Focus on Vehicle Safety and Compliance

We adhere to the highest safety standards for vehicle maintenance and ensure all work is compliant with relevant regulations.

On-Site Vehicle Service and Support

We offer on-site vehicle maintenance and repair, bringing our expertise and equipment directly to your location, saving you time and transport costs.

Specialised Mining Vehicle Expertise

Our mechanics are highly trained in working with all types of mining vehicles, from heavy haul trucks and excavators to dozers, loaders, and support vehicles.

Perth Mining Vehicle Maintenance Specialists

Regular maintenance of mining vehicles is essential to ensure safety and efficiency in challenging mining environments. Routine checks and servicing help identify potential issues before they lead to equipment failure, thereby reducing downtime and maintaining productivity. From oil changes to system checks, maintaining vehicles is the backbone of reliable mining operations. West Fleet Care offers a full range of maintenance services, including lubrication, inspections, and component replacements, all customised to meet the specific needs of your fleet.

In addition to hands-on maintenance, we provide consultancy and technical support to optimise your fleet’s performance. Our experts offer guidance on best practices, maintenance scheduling, and system upgrades, ensuring your vehicles are prepared for demanding tasks. Whether you require a one-time consultation or ongoing support, West Fleet Care delivers reliable solutions to keep your mining vehicles in optimal condition.

Services We Offer

Mining Vehicle Maintenance & Repairs in Perth

Industry-leading services designed to meet all your mining vehicle maintenance and repair needs, maintain peak performance and extended vehicle lifespan.

Major Repairing and Servicing

Complete overhauls to restore vehicle reliability, extending its lifespan and ensuring consistent performance in challenging mining conditions.

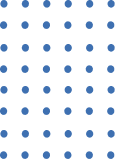

Hydraulics Cylinder Repairs

Specialised repairs for hydraulic systems to ensure smooth operations, reduce leaks, and maximise the efficiency of critical machinery.

Machine and Component Repairs

Detailed repairs for individual machine parts, keeping equipment functional and minimising interruptions to your mining processes.

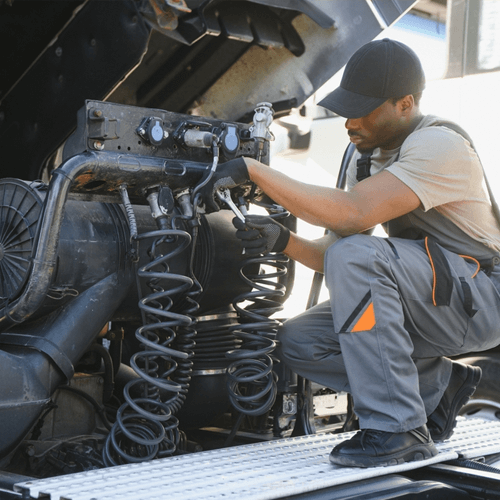

General Wiring & Repairs

Electrical system checks and repairs, ensuring all components operate safely and efficiently, reducing risks of downtime.

Equipment and Scheduled Servicing

Preventative servicing to maintain equipment reliability, improve performance, and minimise costly unscheduled breakdowns.

Frequently Asked Questions

Mining vehicle maintenance typically includes regular inspections of the engine, brakes, transmission, and suspension systems. It also involves checking fluid levels, replacing filters, and ensuring that tires are properly inflated and in good condition. Regular maintenance helps prevent breakdowns and extends the life of the vehicle.

Maintenance frequency depends on the type of vehicle and its usage. Generally, it’s recommended to conduct a thorough inspection every 250 to 500 hours of operation or every three to six months. For vehicles operating in harsh conditions, more frequent checks may be necessary to ensure optimal performance and safety.

Common signs include unusual noises from the engine or brakes, warning lights on the dashboard, difficulty steering, and decreased performance or fuel efficiency. If you notice any leaks under the vehicle or if it vibrates excessively while driving, these could also indicate that maintenance is needed.

While some basic tasks like checking fluid levels or changing air filters can be done by operators, most maintenance tasks should be performed by qualified professionals. This ensures that all work meets safety standards and that any potential issues are correctly diagnosed and addressed.

A typical service includes a comprehensive inspection of all major systems, fluid changes (like oil and coolant), brake checks, tire rotations, and alignment adjustments if necessary. Technicians will also look for signs of wear and replace any components that are nearing the end of their life to prevent future breakdowns.

To enhance the lifespan of your mining vehicles, adhere to a regular maintenance schedule, ensure proper operation by trained personnel, and use high-quality parts during repairs. Additionally, keeping vehicles clean and free from dirt and debris can help prevent corrosion and mechanical issues.

Preventative maintenance helps identify potential issues before they become serious problems, reducing downtime and repair costs. It also improves safety by ensuring that all systems are functioning correctly and can enhance fuel efficiency by keeping engines running smoothly.

If your mining vehicle breaks down, first ensure that it is safely parked away from traffic or hazards. Notify your supervisor immediately and contact your maintenance team for assistance. Providing details about the issue can help technicians prepare for repairs when they arrive.

Yes, there are strict regulations regarding mining vehicle maintenance in Australia to ensure safety and compliance with industry standards. These include adhering to guidelines set by Safe Work Australia and maintaining records of all inspections and repairs performed on vehicles. Regular training for operators on safety practices is also essential.

To become a Mining Vehicle Mechanic in Australia, you need to finish Year 10 of secondary school and then complete a Certificate III in Heavy Commercial Vehicle Mechanical Technology through a four-year apprenticeship. This apprenticeship gives you hands-on experience working with qualified tradespeople, focusing on inspecting, servicing, and repairing heavy diesel engines and systems. You will also receive essential workplace safety training. Depending on your state or territory, you may need a license after completing your training and apprenticeship.