Mining Truck Steering & Suspension

Repairs in Perth

Precision repairs and replacements to maintain smooth & stable steering,

reliable suspension, &

optimal performance for your mining trucks on rough terrains.

Perth’s Trusted Experts in Steering & Suspension Repairs

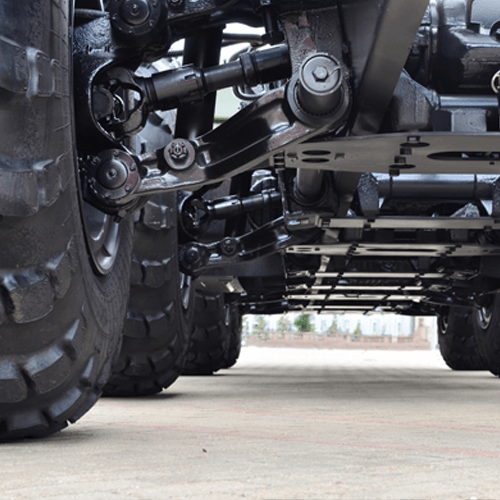

The steering and suspension systems in mining trucks are necessary for maintaining control & stability over challenging terrains. The steering system allows precise navigation, while the suspension system absorbs shocks from uneven surfaces, to maintain a smoother ride and reduce driver fatigue. Over time, constant wear can lead to issues like misalignment, worn bearings, or damaged axles. Which can cause the vehicle to pull to one side or result in a bumpy ride, affecting safety and performance. Neglecting these systems can result in increased wear and tear, leading to costly repairs and potential safety hazards.

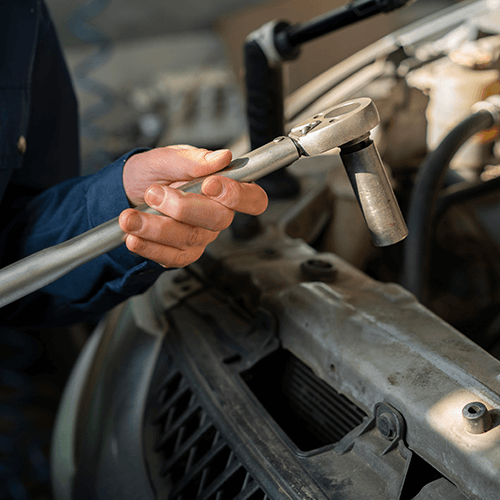

At West Fleet Care, we specialise in diagnosing and repairing these critical systems. Our expert team uses industry-leading tools to inspect components, replace faulty parts, and restore full functionality. From addressing steering shaft problems to enhancing suspension durability, we ensure your fleet operates safely and efficiently, minimising costly downtime on mining sites.

Reliable Steering & Suspension Solutions

Maintain Your Mining Fleet's

Safety & Performance

USABILITY

Smooth and precise handling improves vehicle control, allowing operators to navigate challenging terrains and narrowed spaces with ease and confidence.

FLEXIBILITY

Durable suspension systems adapt to heavy loads and rough conditions, sustaining peak performance without compromising comfort or control.

SAFETY

Properly maintained steering and suspension systems reduce risks of accidents, keeping operators and on-site workers safe from potential hazards.

RELIABILITY

High-quality repairs prevent unexpected breakdowns, maintaining consistent performance and uninterrupted operations in demanding mining environments.

Services We Offer

Mining Truck Steering & Suspension

Repair and Replacement

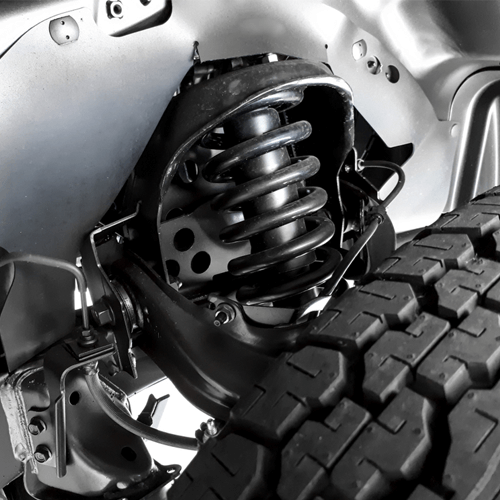

Differentials, Axles, and Transmissions

Repairing gears, bearings, and housings in these components improves power delivery to wheels, fixes uneven performance, and prevents loss of control.

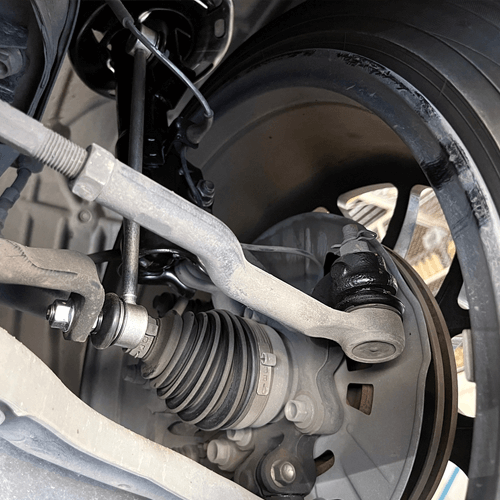

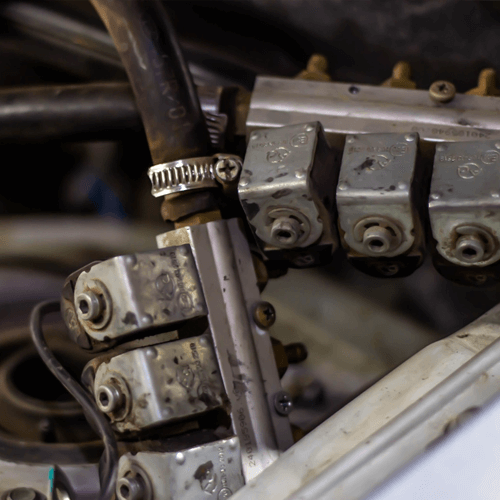

OEM Spec Universal Joints and Centre Bearings

Replacing joints and bearings reduces vibrations, ensures smooth rotational motion, and maintains reliable movement throughout the drivetrain.

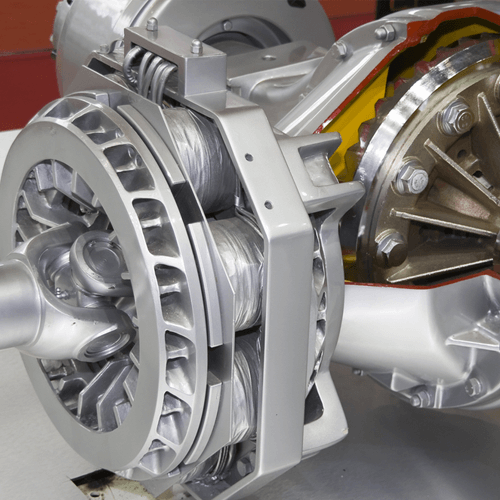

Steering Shafts and Knuckles

Fixing shafts and knuckles restores accurate alignment, enhances steering response, and reduces risks of mechanical failure for safer driving.

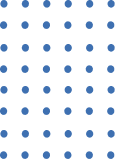

Suspension for Underground Mining

Repairing springs, dampers, and linkages handles extra wear from tough environments, ensuring stable, durable, and comfortable rides for mining vehicles.

Driveshaft Design, Repair, and Balancing

Restoring yokes, tubes, and joints eliminates shaking, improves power delivery, and sustains smoother, safer operation of the truck.

Tail shaft Repairs and Balancing

Fixing and balancing tail shaft tubes, yokes, and slip joints reduces noise, eliminates vibration, and extends the lifespan of drivetrain components.

Why Choose West Fleet Care?

Specialised Mining Trucks Repair Expertise

Years of experience in mining truck steering and suspension systems deliver reliable solutions for optimal fleet performance.

Advanced Diagnostic Tools

Advanced equipment ensures accurate identification of issues and efficient, effective repairs for all fleet components.

Certified Technicians

Our trained experts bring precision and skill to every job, ensuring long-lasting results for your fleet.

Commitment to Safety

Strict adherence to safety standards protects your fleet, minimising risks and downtime during operations.

Frequently Asked Questions

Common signs include excessive bouncing, difficulty steering, uneven tyre wear, and a rough ride. If you notice your truck swaying or pulling to one side, it may indicate worn-out shock absorbers or springs. Regular inspections can help catch these issues early and prevent more extensive repairs later.

It’s advisable to conduct regular maintenance checks every 1,000 hours of operation or at least once a year. This includes inspecting shock absorbers, springs, and other suspension components for wear and tear. Keeping up with maintenance helps ensure safety and prolongs the lifespan of your equipment.

Replacing old steering components can significantly improve handling and safety. Worn parts can lead to poor steering response, making it harder to control the vehicle, especially on rough terrain. New components enhance stability and can prevent accidents caused by steering failure.

Signs that your steering system may need repair include difficulty turning the wheel, unusual noises when steering, or a loose feeling in the steering mechanism. If you experience any of these symptoms, it’s crucial to have your truck inspected by a professional to avoid further damage.

Mining trucks typically use hydro-pneumatic suspension systems due to their ability to absorb shocks from rough terrain effectively. These systems provide better stability and comfort compared to traditional suspensions, which is essential for maintaining productivity in

challenging environments. the wheel, unusual noises when steering, or a loose feeling in the steering mechanism. If you experience any of these symptoms, it’s crucial to have your truck inspected by a professional to avoid further damage.

When replacing parts, it’s best to use Original Equipment Manufacturer (OEM) parts or high- quality aftermarket alternatives that meet OEM specifications. Go for well regarded brands in the industry for their durability and reliability in harsh mining conditions.

The cost of suspension repairs can vary widely based on the extent of the damage and the specific components that need replacement. On average, minor repairs might range from AUD 1,500 to AUD 3,000, while extensive replacements could exceed AUD 10,000. It’s best to obtain quotes from service providers for a more accurate estimate.

The duration of suspension repairs depends on the complexity of the work required. Minor repairs may take a few hours, while complete replacements could take several days. Discussing

timelines with your service provider before starting work can help you plan accordingly.